-

Taurian Radial Conveyor

Key Benefits

- Maximized Stockpile Capacity

- Reduced Material Segregation and Degradation

- Versatile Applications

- Ease of Maintenance and Durability

- Automation and Control

Transform Your Bulk Material Handling with the Telescopic Radial Conveyor

Unmatched Flexibility and Efficiency with Our Telestack Radial Telescopic Conveyor

Engineered for superior bulk material handling, our Telestack Radial Telescopic Conveyor is designed to maximize stockpile volumes and operational efficiency. It effectively handles a variety of materials, ensuring minimal segregation, degradation, and contamination.

The Telestack Radial Telescopic Conveyor features an extendable boom and radial motion capabilities, providing precise material placement and reducing the need for additional `handling equipment. Its advanced PLC systems automate the stockpiling process, delivering consistent performance in the most demanding conditions.

Enhance Your Material Handling Operations with Proven Telestack Reliability

- Maximized Stockpile Capacity +

-

The telescopic design allows for a 30% larger stockpile capacity compared to conventional systems, optimizing space utilization and minimizing operational costs.

- Reduced Material Segregation and Degradation +

-

The fully automated PLC control systems ensure precise stockpiling, reducing segregation, degradation, and contamination of materials, which maintains product integrity.

- Versatile Applications +

-

Telestack conveyors are suitable for handling various bulk materials, from aggregates to coal, ensuring operational flexibility and adaptability across different industries.

- Ease of Maintenance and Durability +

-

Built to withstand the toughest conditions, our conveyors feature robust construction with easily replaceable wear parts, reducing downtime and maintenance costs.

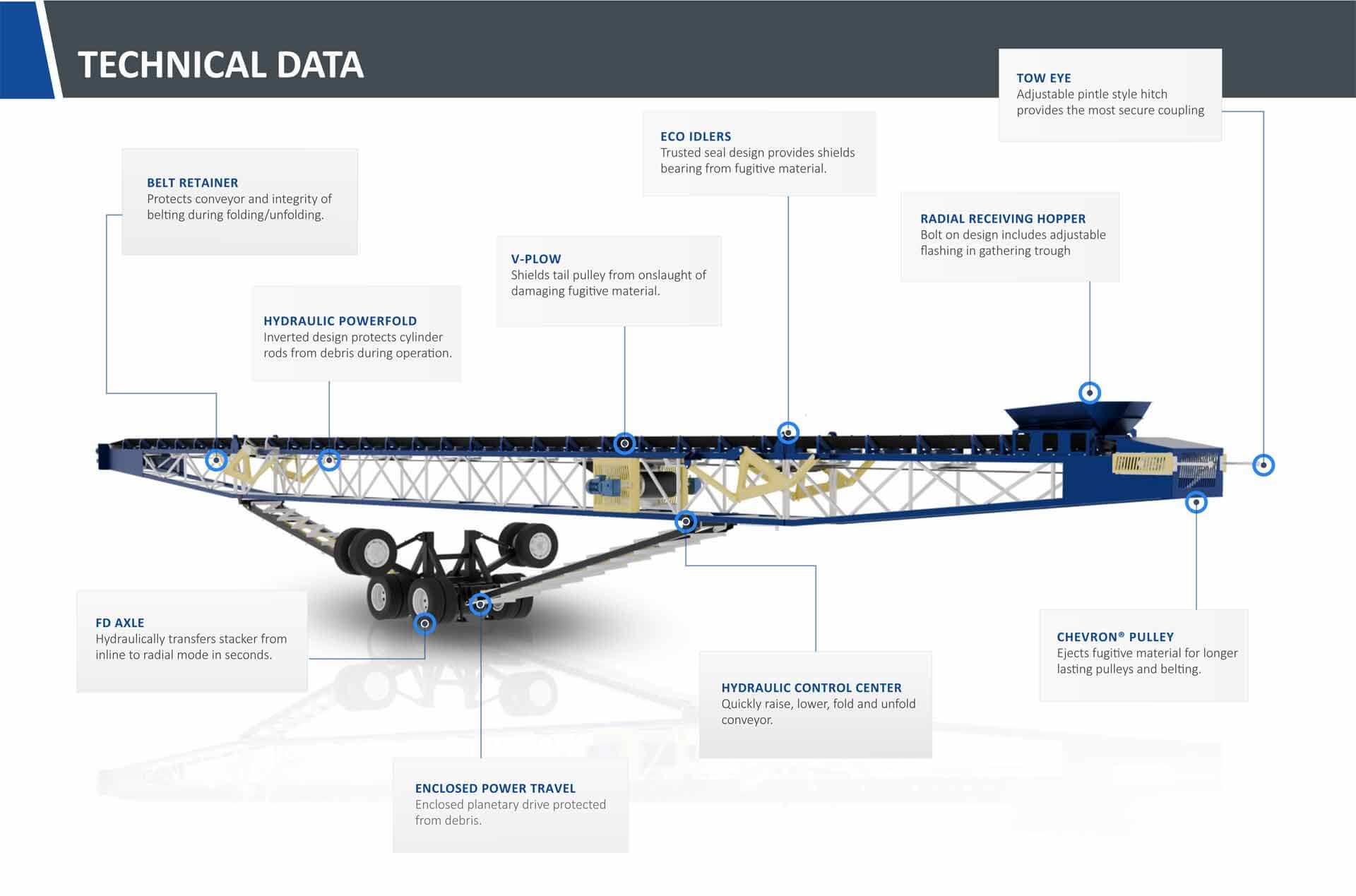

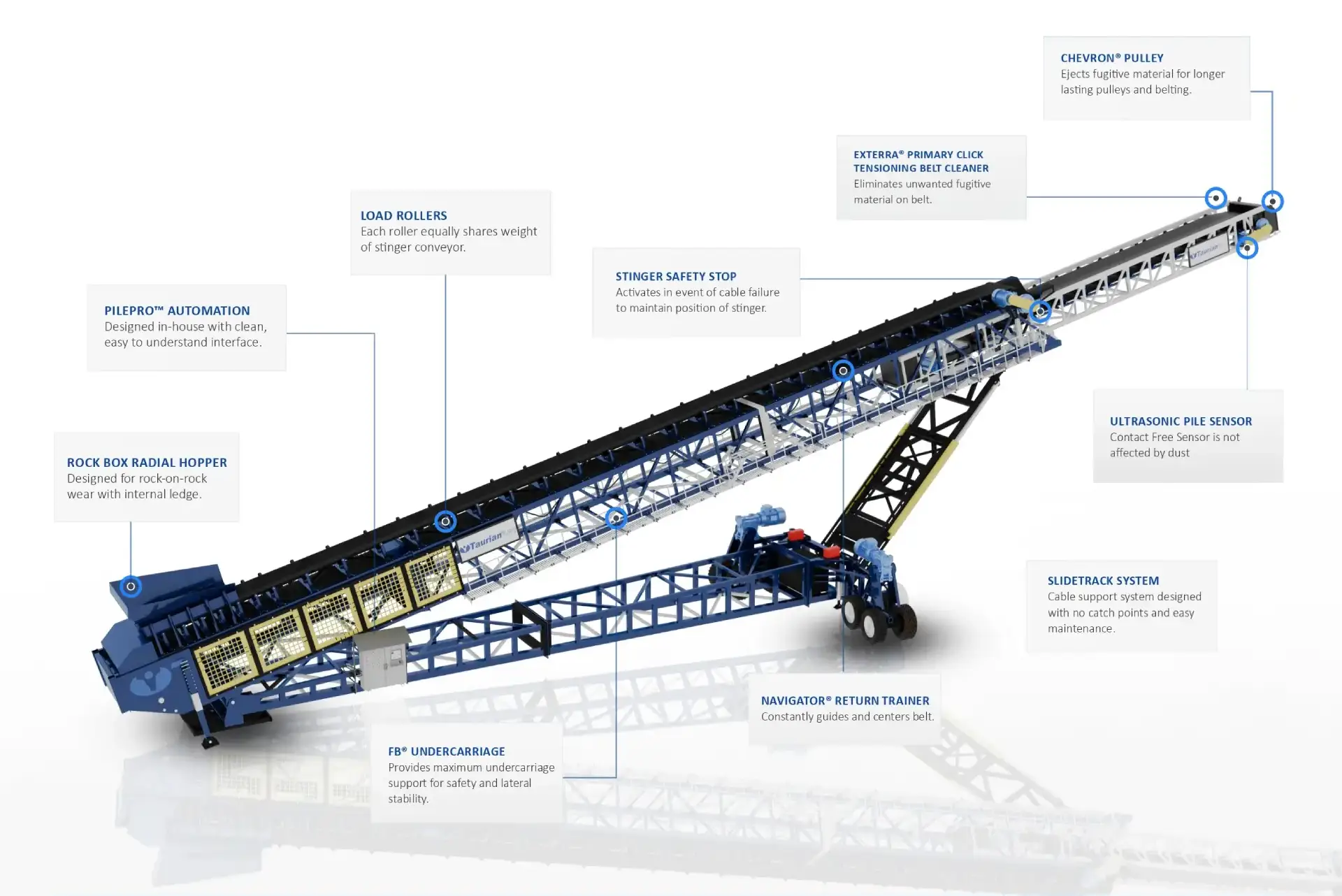

Innovative Design and Advanced Technology for Superior Performance

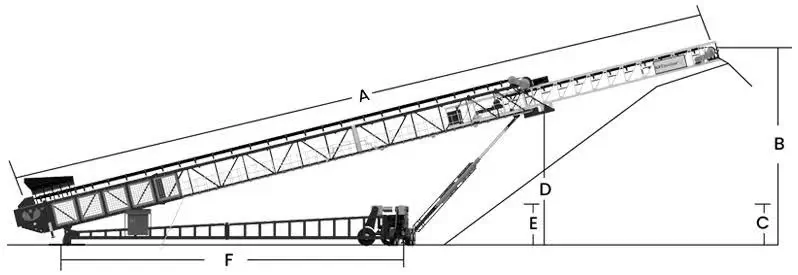

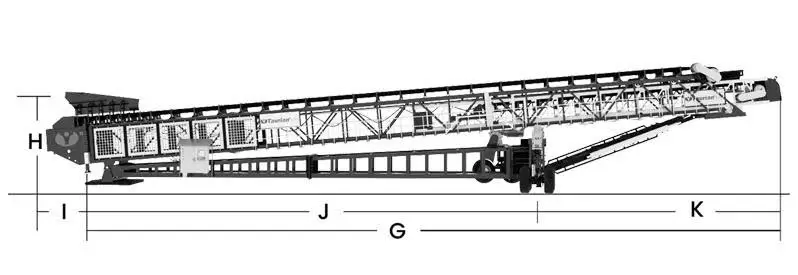

TECHNICAL SPECIFICATIONS

Operating Specification

| Specification | 40 (m) | 45 (m) | 50 (m) |

| Conveyor Length (A) | 40 | 45 | 52 |

| Highest Extended Discharge Height (B) | 14 | 16 | 18.5 |

| Lowest Extended Discharge Height (C) | 4.3 | 4.8 | 4.5 |

| Highest Retracted Discharge Height (D) | 8 | 9.5 | 11 |

| Lowest Retracted Discharge Height (E) | 2.9 | 3.2 | 3.2 |

| Anchor Pivot to Center of Axle (F) | 15 | 17 | 23 |

Travel Specification

| Specification | 40 (m) | 45 (m) | 50 (m) |

| Travel Length – Kingpin to Rear (G) | 21.2 | 24.3 | 30.5 |

| Travel Height (H) | 3.8 | 4.2 | 4.2 |

| Travel Width | 3.6 | 3.6 | 3.6 |

| Kingpin to End of Tow Eye (J) | 2 | 2 | 2.0 |

| Kingpin to Axle (K) | 15.9 | 18.2 | 23.5 |

| Axle to Head Pulley | 5.3 | 6.1 | 6.9 |

| Weight at Axle – 900 mm Belt Width | 15,605 | 17,235 | 20,865 |

| Weight at Kingpin – 900 mm Belt Width | 8,845 | 8,414 | 9,464 |

Tab 3 Content

This is the content for Tab 3.